Railroad Approved Strap Railroad Approved Strap

Webbing 12,000 lbs BS BOX OF 10 Straps

What are Winch Straps?

Winch Straps, also known around the professional flatbed industry as Flatbed Winch Straps and a type of tie-down strap used to secure heavy, oversized, or oddly shaped cargo.

Winch Straps are made from polyester tie-down webbing in the common lengths of 27’ and 30’ long and are tightened into place using installed winches along the outer rails of flatbed trailers. Winch Straps are considered a cheaper and equally effective alternative to traditional ratchet tie-down straps and are made from the same polyester tie-down webbing and end-fitting hardware.

In this blog post, we will be going over why flatbed truck drivers should consider equipping their rigs with winch straps to save money, save time, and become safer in the process. Let’s begin.

The Differences Between Winch Straps and Ratchet Straps for Flatbeds

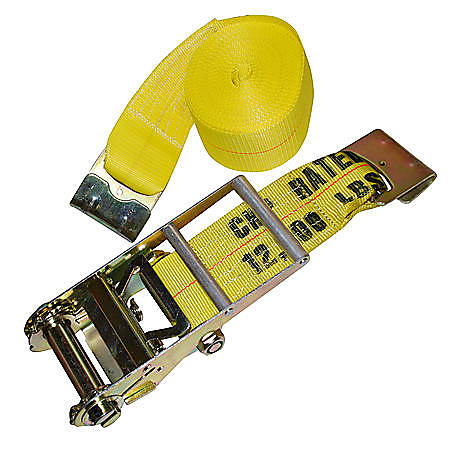

The main difference between winch straps and ratchet straps is the way that the two straps are tightened into place. Ratchet Straps use the ratchet hardware that flows in one direction to tighten the straps into place, whereas the winch straps use installed winches along the sides of a flatbed trailer.

When it comes to replacing Ratchet Straps you often have to replace the metal hardware as well which can often be quite costly as the 3 and 4-inch Ratchet Hardware are over 12 inches in length and weigh over 8 lbs per ratchet hardware. This makes winch straps the cheaper alternative and much easier to replace or equip a flatbed fleet with without becoming less safe in the process.

Both of these straps are made from high-quality and yet durable polyester tie-down webbing that is designed to provide excellent strength, added durability, and stretch very little to help ensure once the cargo is tightened safely in place it is not at risk of coming undone or moving out of place.

Ultimately, your decision should be based on your preferences and specific hauling needs. Both of these strap options provide effective ways to keep your cargo safe during transportation and there is no wrong answer when selecting the ideal strap. Whether you go for the smooth ratchet operation or the convenient winch track system you can rest assured that your cargo will stay firmly in place throughout the journey.

The Different Sizes of Flatbed Winch Straps

There are several different sizes of Flatbed Winch Straps ranging from 2-inch, 3-inch, and 4-inch wide winch straps. Some of the different end-fitting hardware can range from Wire Hooks, Flat Hooks, Delta Rings, and Chain and Hook to name a few of the most popular options. Although winch straps with flat hooks are the most common type of winch straps for flatbed trailers due to their price and ability to secure cargo safely. The most common lengths of winch straps are by far 27 feet long followed by 30 feet in length.

At Lodi Metals we can custom-make winch straps for any length of webbing as most of our straps are made to order. One of the key things to look for when determining which winch strap works best for your securement applications is to determine the working load limit that you need to keep your cargo safe. A 2-inch winch strap often offers 3,335 lbs working load limit to upwards of 5,400 lbs or greater for some of our 4-inch winch strap sizes.

Once you have the end fitting hardware picked out, and the working load limit to keep you safe, you can then determine if you are wanting a different color of tie-down webbing or if you wanted to stick with our standard yellow winch strap options. We sell most of our winch straps in singles, but we do have Boxes of 10 pieces in some of our more frequently purchased combinations at great prices.

What are Flatbed Winch Straps Made From?

Winch Straps are commonly made from heavy-duty polyester tie-down webbing that is 2 inches, 3 inches, or 4 inches in width. This provides you with great options for choosing straps that are designed around the weight of your cargo to ensure that your cargo remains safely in place throughout transit.

Polyester is the webbing of choice for winch straps as it provides excellent strength and minimal stretching compared to alternative tie-down webbings such as nylon which stretch much greater and can cause your cargo to become unsecured if the straps stretch too much. Polyester is extremely durable while outside in the elements such as in direct sunlight, cold weather, extreme heat, rain, snow, ice, and strong winds.

The metal hardware on winch straps is made from a heavy-duty metal construction and is zinc coated to help protect the hardware while outside in the elements for long periods against corrosion. This combined with the polyester webbing not only provides you with excellent strength but excellent durability to help keep you and your cargo safe while on the road.

How to Tighten Flatbed Winch Straps Step by Step Instructions

When it comes to tightening flatbed winch straps on a flatbed trailer there are some crucial steps to follow to secure the cargo safely during transportation. Here are some of the step-by-step instructions to help you tighten the winch straps into place:

Materials Needed:

• Flatbed Winch Straps – we recommend 2” x 27’ or 4” x 30’ depending on the working load limit of the cargo you are transporting. Flat hook end fittings are the most popular type of winch straps for securing cargo.

• Flatbed Winches (installed on the flatbed trailer)

• Cargo loaded on the trailer ready to be secured into place

Step-by-Step Instructions:

1). Position the Cargo – Place the cargo on the flatbed trailer in the desired location. Ensure that the cargo is centered and evenly distributed to maintain balance during transportation.

2). Inspect the Winch Straps – Before using winch straps you will want to inspect the straps for any signs of damage or wear and tear. Check for any burn marks, mold, mildew, cuts, discoloration, fraying, or other damage that you may come across. If the straps are damaged they should not be used and may fail to secure the cargo properly if they are used. If you find the straps to be damaged you should immediately throw the straps away and purchase new winch straps.

3). Thread the Straps Through the Winches – Each flatbed winch strap should have a ratchet mechanism and a slot to thread the straps through. Starting from the bottom of the winch insert one of the winch straps into the winch slot. Pull the strap through until there is enough slack to reach the cargo.

4). Secure the Hook to the Cargo – At the end of the winch strap there should be either a flat hook, chain anchor, wire hook, or other end-fitting hardware. Attach this hook securely to a strong anchor point on the cargo. Make sure it is a safe location to do so for the weight of your cargo and make sure it is anchored to a stable part of the load and not to a loose or weak component.

5). Tighten the Straps Into Place – Once the hooks are safely secured you will want to use the winch handle to start to tighten the straps into place. Rotate the winch handle in the direction that tightens the strap which is normally clockwise until the straps are snug and the cargo is secured in place. Be careful to not overtighten the cargo into place as it can cause damage to your cargo or to your winch straps if you are not careful.

6). Check the Tension – The strap should be snug and tightened several more clicks until it is not at risk of moving during transit. Be mindful of how tight you are tightening the slack of the winch straps as the last thing you want to happen is damage the cargo right before you hit the road. If there is any visible movement after tightening the straps further tighten the straps until the load is stable.

7). Secure the Excess Slack – After tightening the straps into place there may be some excess slack or excess webbing that was not used. Secure the loose ends of the strap by either tying it up or by using a rubber strap retainer to prevent it from flapping in the wind as it can become a safety hazard or cause friction burns to the webbing on the strap.

8). Repeat the Process for Other Straps – The process for securing your cargo should be the same way as the first strap that was secured. Additionally, you should always use enough straps that if a strap were to become damaged or destroyed during transit the load wouldn’t be at risk of coming undone as you used enough straps to keep it in place until you can add another strap.

You should also make sure to balance the weight of the cargo by using extra straps to ensure the highest levels of safety are met and the cargo falls within the straps working load limit which is determined by using 1/3 of the breaking strength of the straps to determine.

9). Inspect Your Straps Regularly During Transport – Once the straps are secured in place and you are on the road heading to your next destination take the time during a stop to refuel or to take a quick stretch to inspect your load often. We recommend once every 75 miles of driving or every hour to inspect your load when possible where it is safe to do so. This helps ensure that your load reaches the next destination safely as well as to prevent any potentially dangerous situations from happening.

Shop our Popular Flatbed Winch Straps

Assembly 5,400 lbs WLL

Assembly 5,400 lbs WLL

Assembly 3,335 lbs WLL

Assembly 5,400 lbs WLL

Frequently Asked Winch Strap Questions

Are Flatbed Winch Straps DOT Legal? – Yes, flatbed winch straps are made following the Department of Transportations general cargo securement guidelines, rules, and performance criteria that can be located here.

What is the standard length for Flatbed Winch Straps? – The standard length for most flatbed winch straps would be either 27 feet long or 30 feet long. Depending on the weight of the load it can range from 2 inches, 3 inches, or 4 inches wide to meet a variety of different safe working load limit ratings for your cargo securement needs.

What is the Best Way to Store Flatbed Winch Straps When Not in Use? – The best way to store the straps in-between usage would be by rolling the straps up after inspection. Next, place the straps in a dry and moisture-free area inside the cab of the truck. This will prevent the straps from becoming damaged in-between uses. If this is not an option you can place the straps along the rig in a water-proof compartment or inside of a waterproof bag. One of the leading causes of damage to winch straps is from direct sunlight from the sun over long periods of time so be mindful of that as well when finding a storage location.

What are the Best Ways to Keep Winch Straps in Good Shape for Longer? – One of the best ways to keep winch straps longer lasting is with the use of corner protectors. Corner protectors help to create a barrier between the webbing and sharp edges along the cargo that you are securing that could otherwise cause damage to the straps or cause them to be replaced. Corner protectors are often a great investment for only a few additional dollars per piece to ensure you are getting the most out of your winch straps and come in a variety of sizes, materials, and lengths.

How to use Winch Straps for Cargo Control on Flatbed Trailers

Published on 07/31/23

AAR42000-DR

$15.00

AAR42001-FH

$15.00

A42444WFH-30

$10.50

A42468-Box

$109.99